The Leader in Healthcare Clinical Supply Utilization Management Savings & Quality Improvement Solutions

Quickly Realize an Additional 7% to 15% in Total Supply Budget Savings Beyond Contract Price and Standardization

Are You Ready to Take Your Organization to a Whole New Level of Savings Beyond Price and Standardization?

Let Us Show You the Way!

Robert T. Yokl, CEO and Chief Value Strategist for SVAH Solutions

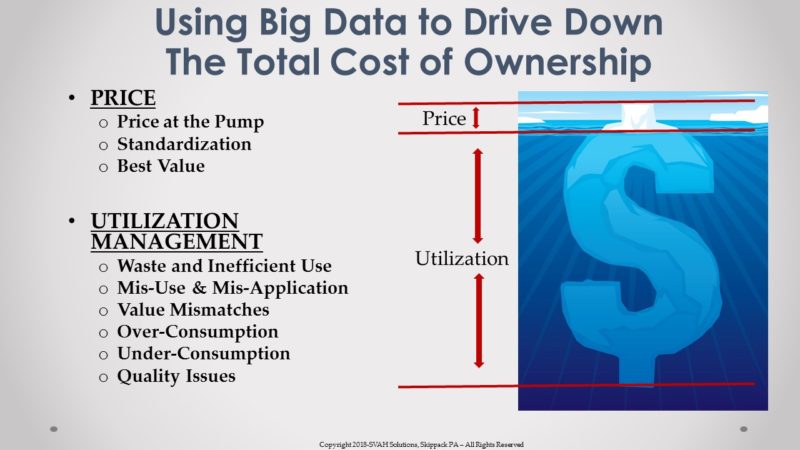

SVAH has been a leader in the field of Value Analysis with a specific focus on savings beyond price or Clinical Supply Utilization Management. With the maturity of group purchasing and custom contracting at organizations, the price at the pump has all been taken care of with regards to savings optimization. But we realized a number of years back that there was still much more that was not being addressed or even reported on, and that was the in-use cost and consumption of these products by the end users, clinicians, and support staff. This savings is the next level of major savings that needs to be addressed moving forward and it is bigger than you would ever imagine.

The Next Level of Major Supply Chain Savings Is There and SVAH Can Assist You in Finding It

How do we assist you to find the next level of supply chain savings beyond price & Standardization?

- Determine WHERE Your Savings Opportunities Are Hidden

- Determine the IMPACT On Your Bottom Line

- Find Your Best Courses of ACTION to Drive Out These Savings

- Align With Your Cost and Quality GOALS & OBJECTIVES

- Establish Better Controls and Monitoring Systems that ENHANCE Your Internal Savings Systems

- IMPROVE Quality and Patient Outcomes

- SUSTAIN Your Savings Over The Long Term

Proven Tools and Strategies to Help You Uncover the Hidden Savings in Your Supply Chain, Plus Peace of Mind That You Are Not Leaving Any Dollars on the Table

Better Control

SVAH helps you find, plan, achieve, and control your supply chain expenses by giving you the tools, training, and knowledge to take your supply chain to the next level of savings performance beyond price.

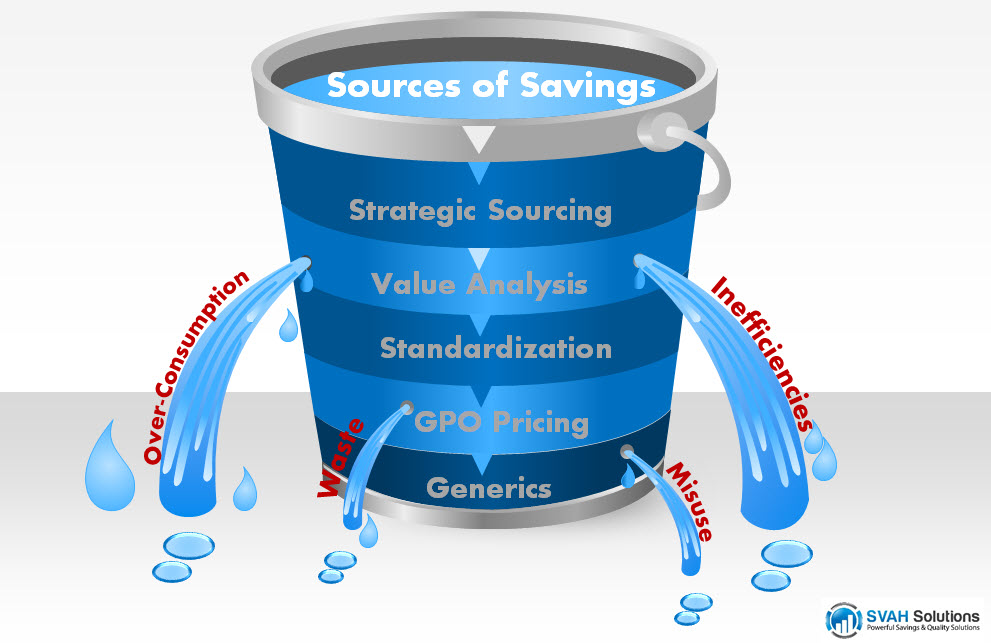

Eliminate Waste

Quickly and easily drive out waste, inefficiencies, misuse, misapplication, and value mismatches from your supply chain. This will free up major savings opportunities you never thought were possible.

Hold Your Gains

Continue to look deeper and more broadly into your supply streams to easily identify and eliminate the wasteful and inefficient practices that have seeped into your supply chain over many years.

The Right Tools and systems make the difference

Look Broader, Dig Deeper, and Touch the Edges of Your Supply Chain to Find New Hidden Savings

Supply chain professionals are always looking for the “next big thing” to squeeze even more savings out of their supply chain expenses. Let me state unequivocally that there really isn’t a next big thing for squeezing more savings out of your supply chain, because they have already been invented and you probably already bought them. The “next big thing” you need to save money is for you to look broader, dig deeper, and touch the edges of your supply chain to find missed opportunities right in your own backyard.

There are still millions to be saved! Every hospital, system, and IDN we have worked with has already bought, joined, or subscribed to the “next big thing” (ERP purchasing information systems, subscribed to evidence databases, joined a regional cooperative, changed their GPO, etc.), but we still find millions of dollars of savings for them that have been hidden from their view.

approach

Shift Your Paradigm to Data-Driven Technology to Become More Efficient

SVAH tools allow you to do more with less effort which will enable you to further identify savings opportunities, track savings, and improve quality within your supply chain.

SVAH tools make reporting fast and easy to create quality savings results. Typically, up to 85% of supply/value analysis professionals' time is spent collecting, validating, and crunching numbers for supply chain savings.

testimonials

Check out what our clients say about us

"SVAH Software Tools have assisted the hospital in taking our cost savings initiatives to the next level. The reporting establishes clear targets of cost and quality improvement opportunities based on actual hospital patient volumes at all levels of the organization. The end result has been a significant reduction of expense in a relatively short time. It is a valuable tool that offers insight on how to manage the supply chain in the present and on an on-going basis."

DIRECTOR OF SUPPLY CHAIN

“These tools provide another approach to our current method of identifying areas of cost saving opportunities. We can go after utilization, as opposed to price reductions, and do this in conjunction with our clinicians. This results in a win-win situation for our organization.”

dIRECTOR OF SUPPLY CHAIN 6-hOSPITAL HEALTH SYSTEM

“We already have a solid value analysis program, quality analytics, and great people! But we still deployed SVAH's Clinical Supply Utilization Tool because of the proven experience, support, and results behind the system that fast-tracked our clinical utilization program from a basic beginner stage to advanced expert in just a few short months!”

VICE PRESIDENT OF SUPPLY CHAIN MANAGEMENT

Find Out How Much Money Your Organization Can Save Today!

Take a No Cost, No Obligation Test Drive of SVAH's Value Analysis and Clinical Supply Utilization Solutions Today

Latest Articles

Looking to Receive Great Savings Strategies and Knowledge In Your Inbox Every Week?Join Our eNewsletter Today and Receive Special Bonus eBook"Healthcare Supply Utilization Revolution - The Future of Supply Expense Management" |

|---|